- The bespoke Turanza Eco tyres were jointly developed to optimise aerodynamics, contributing to a real-world range of 1,000 km on a single charge, which the car manufacturer recently demonstrated in a proof ride.

- The tyresapply Bridgestone’s proprietary ENLITEN and ologic technologies for ultra-low rolling resistance, contributing to an outstanding energy consumption of 8.7 kWh per 100 kilometres on the drive from Sindelfingen to Cassis.

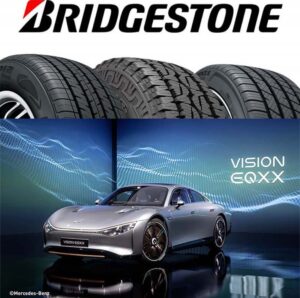

BRUSSELS –Bridgestone has been selected by Mercedes-Benz AGas the development partner for tyres for its technology programme, the Mercedes-BenzVISION EQXX. The futuristic electric vehicle (EV) is the car manufacturer’s answer to making EVs more efficient and increasing electric range to a new level.Bridgestone engineers collaborated with Mercedes-Benz to create custom-designed tyres that have contributed to increasing the vehicle’s efficiency and thus driving range to a real-world 1,000km – from Sindelfingen, Germany to Cassis, France – on a single charge.

Ultra-low rolling resistance and optimised design for an EV that delivers an incredible range in the real world

Bridgestone designed bespoke Turanza Eco tyres that combine its proprietary and lightweight ENLITEN Technology to reduce tyre rolling resistance and weight by up to 20%, along with its ologic technology designed to enhance battery range by means of a large tyre diameter to reduce rolling resistance, and a narrow tyre width to reduce aerodynamic resistance.

In collaboration with Mercedes-Benz’s aerodynamic department, the tyre also comes with optimised sidewalls and a bead area design that match the covers mounted on the 20-inch, forged-magnesium wheels, greatly improving the tyre’s aerodynamics.

Virtual tyre development

The tyres were developed using Bridgestone’s virtual tyre modelling and simulation capabilities,which enable a digital version of an in-development tyre to be created and tested.Using this technology means that development time was cut considerably.

Bridgestone leveraged the virtual environment for a large part of the development process, enabling prediction of how the tyre would perform in different conditions before physically building it. The increased flexibility offered by virtual tyre development enables Bridgestone to test far more variants of a given tyre, thanks to the speed at which modifying a tyre’s digital twin and immediately testing it can take place. Additionally, this virtual tyre development delivers multiple environmental benefits, as both natural resource use and exhaust emissions are cut, thanks to a lower number of prototypes that need to be produced and tested.

A successful co-development

The collaboration on this project sets the stage for the future of EV tyres and is underpinned by a shared EV-ready vision between the companies.

Emilio Tiberio, COO & CTO at Bridgestone EMIA, said: “As part of our commitment to help shape a sustainable future of mobility, Bridgestone is proud to have co-developed with its long-term partner the right tyres for a project as innovative as this. The Mercedes-BenzVISION EQXX isa project that is totally aligned with our own EV ambitions and targets, especially as we are investing to make electric mobility more efficient and accessible through a fully integrated approach. This includes pioneering premium tyres and tyre technologies able to tackle the greatest EV challenges. This is especially true as we heavily invest in EV tyre development – currently allocated over 30% of our R&D resources – and improve upon our technologies in 2022.”